WJ_Lab - Research

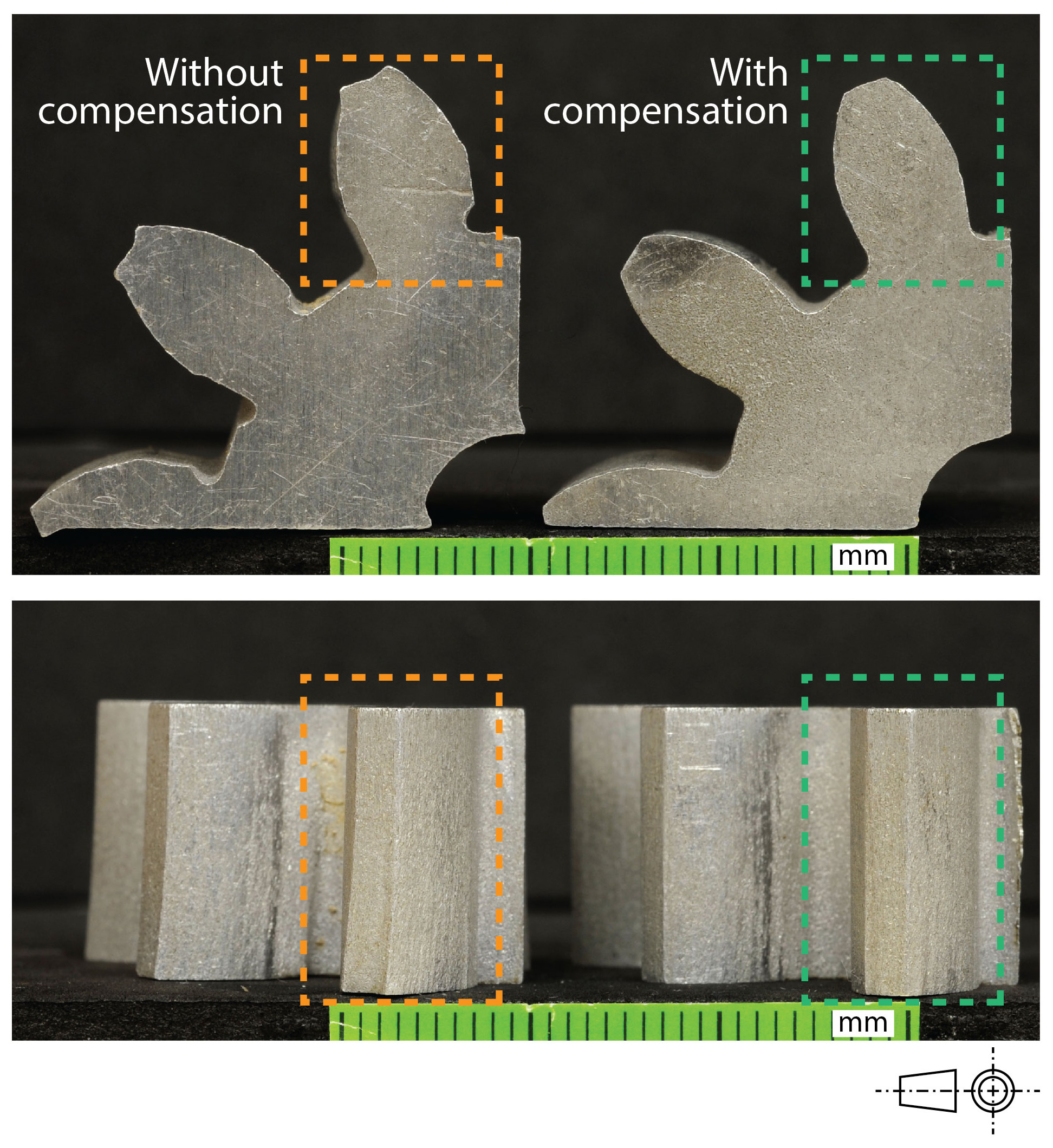

| Cutting defect reduction in conventional AWJ A poor machining quality caused by typical AWJ defects

(i.e waveness, kerf taper and jet lag) often requires further finishing

processes on the part. Defect characterization and measurement on

different materials (i.e. metals, composites and foams) allow to perform

a compensation strategy on a wide thickness range (up to 25 mm). A

5 axis cutting head is exploited to reduce the defect using a conventional

Ø 1.02 mm jet. The result is a near-net-shape part. |

|

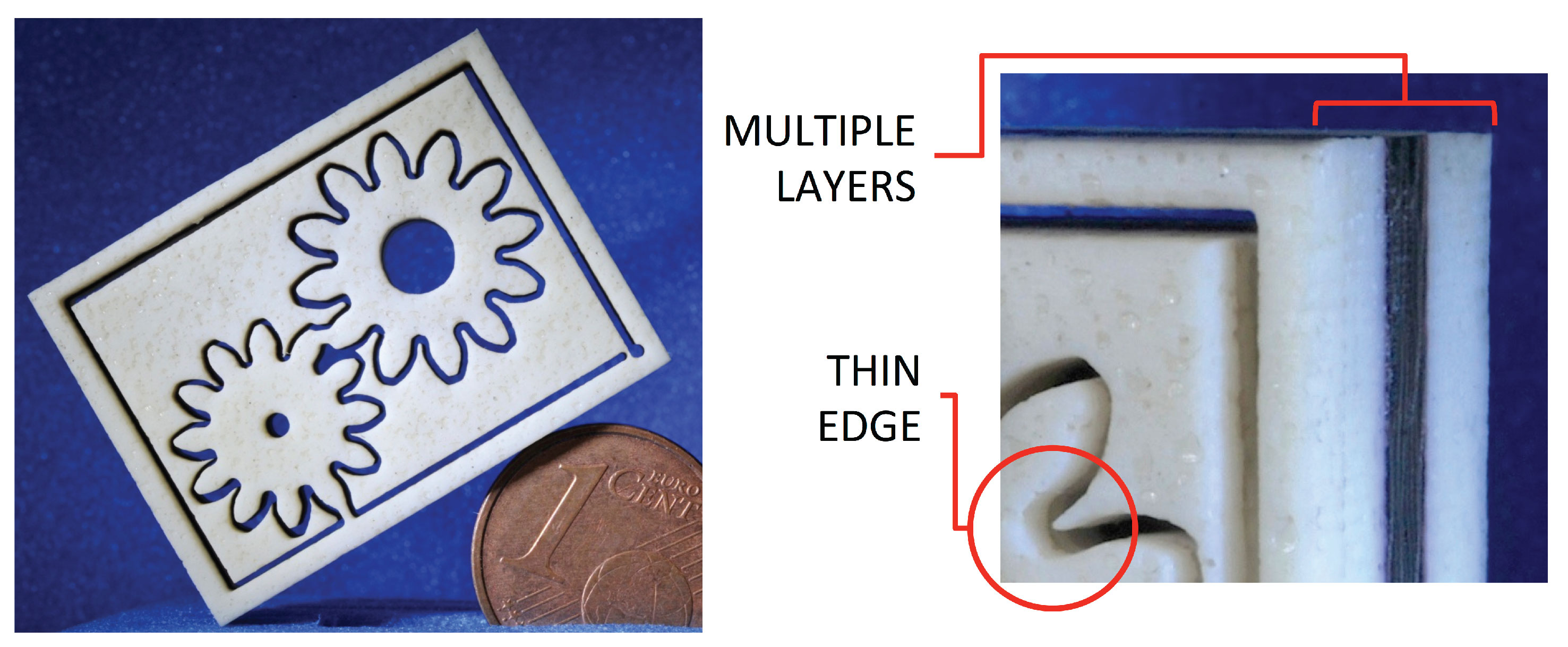

| AWJ miniaturization for fine parts manufacturing The need of small size parts with fine features is a challenge for almost every machining technology. WJ_Lab develops complete "micro AWJ" system prototypes by designing novel components and devices to overcome the downsizing issues. The Ø 0.3 mm jet is mastered by WJ_Lab, thus making it a state-of-the-art reference to be monitored and controlled. The final goal is the Ø 0.1 mm jet, which deserves specific components not still available (i.e. nozzles and mixing chambers) and specifically designed devices (i.e. abrasive feeder and precision handling system). The jet miniaturization is carried on together with

WatAJet S.r.l. (www.watajet.com, a WJ_Lab spin-off) and it is part

of HORIZON 2020 European Community research programme. |

|

WJ_Lab - Partnerships

|